National Steel Supplier and Service Center

We are only as successful as our partners. For us that means providing you with reliability even in times of volatility. We regularly carry over 200 million pounds of steel in various types, gauges, and coatings at a time.

Our stock inventory makes us a reliable contract partner and a top player in the spot market. With 16 locations, you can always count on Majestic to deliver.

THE STEEL WE STOCK

Click any of the below for each steel’s grades, sizes, weights, etc.

- Galvanized

- Aluminized

- Cold Rolled

- Galvalume®

- Galvannealed

- Phosphatized / Bonderized

- Pre-Paint

- Stainless Steel

buying options

However you prefer to buy steel, we work with every partner to make the process as straightforward as possible. Our most common buying options are:

-

Spot

Order the quantity you need with no commitment for future purchases and let our just in time delivery take care of the rest.

-

Contract / Blanket

Utilize the flexibility of contract buying to release material in the quantity and frequency that fits your steel needs.

-

Trade

We leverage our supplier relationships and coordinate delivery of material to your specified location.

processing power

Need slitting, shearing, cutting-to-length or blanking? Majestic can help. Our state-of-the-art processing equipment means your order will be completed on time and to your exact specifications. Majestic processes material as close to the minimum of the gauge as possible, giving you more feet per coil and increasing production yield. Our diverse processing capabilities can fill stock and custom orders. Instead of ordering from multiple locations because of various processing needs, Majestic can handle all of your processing in a single order.

bringing innovation to american steel.

America and Majestic are forged from steel. Railroads were laid to expand the country over the landscape while skyscrapers colonized the sky. From ballparks to back yards, our lives rest on the strength of steel.

At Majestic Steel, steel is not only our foundation, it pushes us forward allowing us to innovate and seek new frontiers. Our warehouses are filled with opportunities for us and our partners. Our talent and innovation provides opportunity to keep building, fortifying, and creating a stronger tomorrow.

Inventory simplified

MANAGE YOUR STEEL INVENTORY FROM ANYWHERE AT ANY TIME WITH MAJESTIC INVENTORY CONTROL SYSTEM (MICS)

Let your warehouse do the talking with real-time visibility to your floor stock levels and A.I. tools that enable auto-restocking of the material you need.

The Auto-Restock mobile user interface makes it easy to make adjustments to your inventory. Whether you are receiving new inventory or making adjustments to your existing inventory, simply scan the barcode and make the necessary adjustment.

Use the mobile app to scan new inventory. As you receive it in your warehouse the app will automatically reconcile your stock levels, so your team stays up to date.

All Majestic customers are eligible for MICS.

making inventory calculations easy

simplifying the steel equation

Whether galvanized, aluminized, pre-painted or cold rolled material, use this app for quick and simple weight, cost and yield calculations. Unravel complex steel calculations with this essential iPad and iPhone application for flat-rolled steel buyers, for free.

MHUB Customer portal

one centralized portal for all your key data

Quickly review order status, purchase history and payment info. Manage contracts. Access purchase orders, invoices, packing lists and certifications. Utilize the toolbox for one-click access to the Core Report and our award-winning steel calculator, Unravel.

Your info on your time, making steel buying easy.

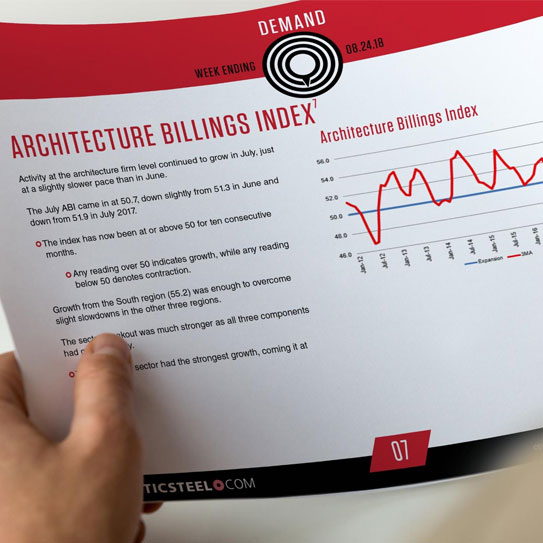

Market information at a glance

Getting the right information at the right time is more important than ever. With the market more volatile than ever we take it upon ourselves to provide our partners with information to make their buying decisions easier.

needs based assessments

Every partner has different needs. We work alongside them to understand exactly what they’re looking for and when they need it.

forecasting to make buying easier and smarter

Unlike other opinion-driven reports, the fact-based nature of the CORE Report is an effective means of cutting through the noise to determine what is really happening in the market. This objective approach does not lead the reader to the author’s desired conclusion; rather it provides the information to help the reader make more educated purchasing and selling decisions.