Is Steel Recyclable?

Discover the Process, 7 Benefits, & Where It’s Re-Used

In a word, yes!

In two words, yes very much so.

The process of recycling steel has evolved over time, and today, steel is the world’s most recycled material. The process of creating recycled material from scrap metal (whether aluminized, cold rolled, galvanized, or galvannealed is also one of the most cost-effective ways to produce new steel.

Recycling steel is an essential component of sustainable development. With global population growth, economic concerns, and a finite amount of natural resources, it’s important that we make sure our raw material use and energy consumption is sustainable.

We should be able to reuse our resources instead of sending them to a landfill, and the steel industry is proud to be leading the way.

Next up, we’ll explore everything you need to know about steel recycling:

- the steel recycling process

- environmental and economic benefits of recycling scrap metals

- key industries benefiting from increased recycling

- what you can do as a consumer to support these practices

Let’s get to it!

The Complex Process of Steel Recycling: 6 Main Steps

Steel’s recycling process is similar to other recyclable metals.

- First, steel scrap is collected and sorted by the type of steel and sent to steel mills or to foundries

- Next, the recycling process begins with the melting down of old steel in a furnace at 3,000 degrees Fahrenheit. The melting allows steel to be separated into different components, including its ferrous and non-ferrous metals.

- Once melted, the separation process begins. Ferrous metals are separated from their non-ferrous counterparts using methods like passing through magnetic fields that can separate materials based on their properties.

- Next, the materials are purified of any contaminants and then sorted by their quality levels into various steel grades.

- The melted steel is then cooled and processed into something usable such as sheets and rolls.

- Finally the materials are sent to their final destination to be transformed into end products like machines, cars, construction beams, appliances, and much much more.

4 Critical Environmental Benefits of Recycling Steel

There are many environmentals benefits of recycling used materials into fresh steel. This is primarily because recycling steel requires much less energy than producing virgin steel.

For example, when a ton of steel is recycled, it uses up to 74% less energy than when steel is produced from raw iron ore into a processed format like a steel sheet.

Recycling Steel Facts:

- Recycled steel saves the equivalent energy to power 18 million homes for a year.

- Using scrap steel can reduce CO2 emissions by 58% due in large part to reducing the need to mine, smelt, and transport iron ore.

- Each ton of recycled steel saves 2,500 lbs of iron ore, 1,400 lbs of coal, and 120 lbs of limestone.

- The annual amount of U.S. recycled ferrous scrap weighs enough to build 900 Golden Gate Bridges.

3 Important Economic Benefits of Recycling Scrap Metal

The United States consumes about 94 million tons of steel annually. American industry chooses to use recycled steel because it is just as reliable, and in many cases more affordable, than virgin material from a steel mill.

- Job Creation & Local Economic Growth

The fast-growing scrap recycling industry has created over 450,000 jobs and added millions in tax revenue – up to $10 billion for state governments. Recycling companies are making ever growing contributions to their local economies, and they’re expected to continue creating job opportunities.

2. Reduced Input Costs

Because recycled steel is less expensive to produce than virgin steel, these savings can be passed from steel mills to manufacturers. And by reducing the cost to produce their product, prices can be made less expensive for end consumers.

3. Reduced Reliance on Imports

Imported steel can be of lower quality and have high emissions because of the long distances it needs to travel overseas. However, by recycling steel, we are able to increase domestic supply and manufacturers do not need to rely on steel imports because there is enough in the local market.

2 Key Industries Utilizing Steel Recycling

Steel is used in a wide variety of industries, from construction to transportation to manufacturing. It’s also the metal of choice for many sectors of the automotive industry, such as auto body repair, metal fabricators and wheel manufacturers.

- Construction

98% of all structural steel is recycled back into new steel, and as discussed above, recycled steel has the same strength and reliability as virgin steel. In many cases, steel used by the construction industry is recycled multiple times and used in more than one building.

Steel is not just used in buildings, it’s also used in the materials that build buildings —anything from cranes to drills and shovels. It can also be found in large civil engineering projects like bridges because the material lends itself well to high-rise structures.

Recycled steel has been known by some civil and building engineers as “the greenest element” due to its ability not only resist corrosion but also maintain structural integrity over time without losing any weight or density due to oxidation when exposed air.

2. Automotive

Automobiles are the most recycled consumer product.

Every year, more than 14 million tons of steel is recycled from vehicles that are no longer being used and have been taken off of the roads. That amount of steel is equivalent to what would go into nearly 13.5 million automobiles. Interestingly, the amount of steel recycled from automobiles each year is roughly the same amount that is used to produce new cars. Meaning, the automotive industry has an almost 100% recycling rate.

65% of the average car is steel, and the steel used in a car’s body is an average of 25% recycled steel. In addition to the car’s body, internal parts such as the engine can have an even higher percentage of recycled material.

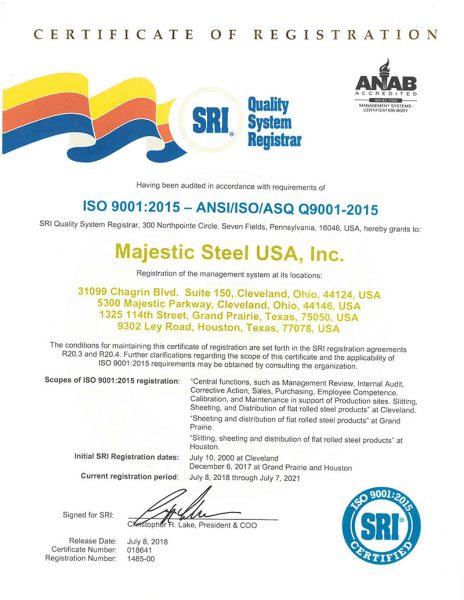

Majestic Steel is committed to recycling steel scrap as well as buying recycled steels directly from the mills. If you’d like to learn more about our processes and inquire about becoming a customer please get in contact with us.

The Majestic Steel Way: Why You Should Consider Us

The best way to support the steel recycling process is to buy recycled steel and products made from it.

Ask your suppliers what their sustainability practices are and evaluate your own practices. Partnering with sustainable suppliers promotes and encourages recycling steel. In the long run this practice:

- cuts costs for both producers and consumers of steel products

- reduces the amount of materials in landfills

- improves the health of both the economy and environment

We believe that the future will be built on steel, but in order to get there we have to start building today. As members of the steel industry and champions of American manufacturing we know starting with more sustainable steel practices is how we’ll get there.

Through our own homegrown operational excellence program, MissionZero, we focus on the little things we can do today to support the bigger picture. Since its inception we’ve recycled 32 million lbs. of steel, averaging 10.65 million lbs. per year.

Our scrap recycling program saves 132,000 lbs of steel from landfills every year. As we continue to grow, we push ourselves to save more and find new and better ways to keep our plants green.

We’ve seen these programs save us time, money, and energy. They’re a key part of what makes our business so efficient. If we all prioritize making small changes in our businesses the impact can be much greater.

If you’d like to learn more about Majestic Steel and inquire about purchasing our products you can get in touch with a member of our sales team here.