Why mini mills steel production is crucial for your business

MINI MILLS STEEL PRODUCTION CREATES SUPPLY FLEXIBILITY

What is a mini-mill?

Like integrated mills, mini-mills are capable of the entire steel production process, from the melting of raw materials all the way through processing a finished coil. However, mini-mills utilize an Electric Arc Furnace to melt a mix of 80% steel scrap and 20% other iron-rich materials into molten steel. Once molten it is casted, rolled, and finished into coils. Because mini-mills can increase and decrease production capacity with more ease than Basic Oxygen Furnaces they are more flexible and cost-effective.

How do they affect the market?

Mills have a lot of influence when it comes to steel supply and lead times. Mini-mills use mostly steel scrap in their operations. The availability of steel scrap is essential to mini-mill production and the cost of steel produced by these mills. Mills factor in their cost of materials, demand, and lead times while setting their price for steel, which can trickle down to other parts of the supply chain like service centers, manufactures, and end-users.

What should you do?

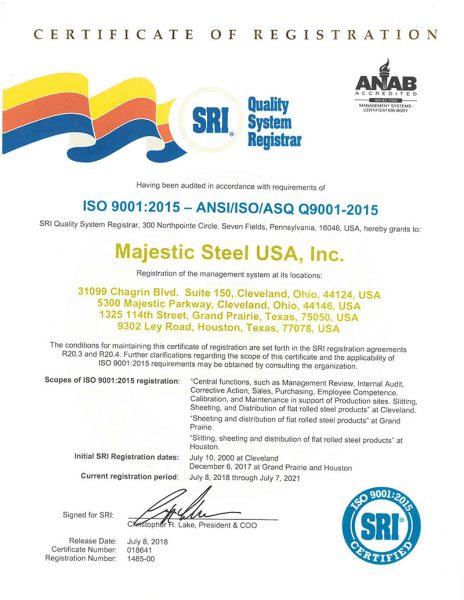

Although there is greater flexibility in production at mini-mills, it is still important to be aware of their current production capacity as it can impact lead times and available inventory. Additionally, being aware of scrap’s availability is important when considering mini-mills production capacity. Majestic’s CORE Report follows mills’ production, pricing, and lead times; along with scrap prices every week to see where the market stands.